|

pV/T Master ™ - Volumetric Analyzer lab in-one

The pV/T Master™ is a novel and versatile volumetric analyzer that allows implementation of variety of static and dynamic techniques by using the core instrument and optional or user provided ancillary hardware. As presented, the basic instrument can be used for volume (density) measurements of any solid state samples and compressibility studies of cellular materials (foams) using gas expansion technique or time domain pycnometry. The open-architecture design allows for using all resources for variety of research activities.

|

Design features (basic instrument, as shown):

- Automatic and Manual modes (hardware and software)

- Volume (density) determinations using pressure or vacuum

- Compressibility profiles of foams versus pressure and pressure intervals

- Software controlled miniature vacuum pump (<10 kPa capability)

- Mass flow controller for implementing of dynamic operation

- Precision low pressure regulator for setting repeatable pressure values

- Absolute pressure transducer (typically 50 psia, 340 kPa)

- Hermetically closed sample holders (No elutriation for fine powders)

- (Optional) flow-through sample holders for controlled purge

- Introduction of time-domain pycnometer

- Added ports for usage of analyzer resources

- Unique software design to create experiments from preprogrammed functionalities

- Extended software features beyond pycnometry for recording data from various experimentation

- Easy interfacing with external hardware to implement additional capabilities

- Availability of additional temperature sensor (RTD, typically -50ºC to 150ºC)

|

Possible extensions:

|

Foam Compressibility vs Pressure / Vacuum

|

P=220 kPa

|

P=101 kPa

|

P=7 kPa

|

|

Application notes (pdf):

|

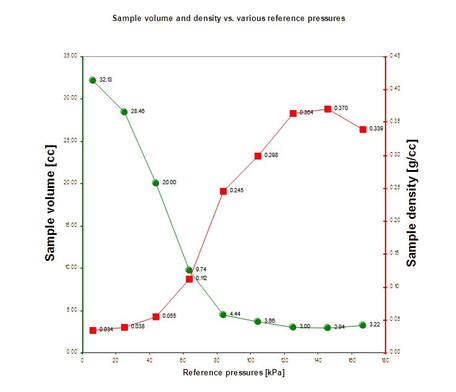

In general, density of compressible (cellular) materials cannot be described by a single number but rather by a range of values. This technical note presents a new instrumental and methodological approach for studying materials that can change their volume versus pressure, like easily compressible foams with closed cells.

|

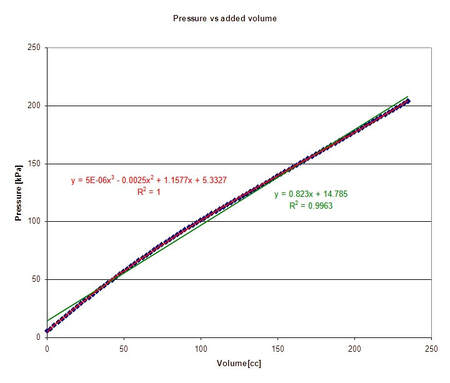

Combining dynamic (flow type) and static (gas expansion) modes in one instrument forms a highly capable and novel gas (helium) pycnometer. This technical note presents overview of a new instrumental and methodological approach for materials characterization as well as other possible applications of this volumetric analyzer. |

Absolute method of determination of specific surface area of powders is being proposed. Development of a versatile volumetric analyzer, pV/T Master, and ancillary hardware allows for carrying out all measurements using one instrument. Better implementation of the permeametry technique can make it more effective in characterization of powders. |

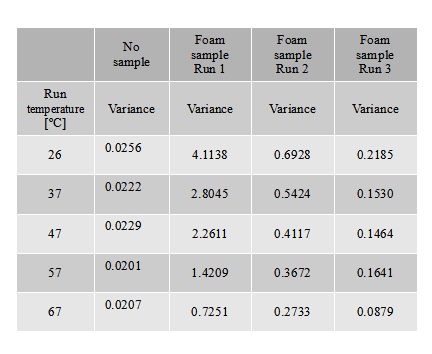

4. Testing of compressible materials and their thermal degradation using time-domain mode of the volumetric analyzer pV/T Master™ and external temperature-controlled chamberAddition of a separate thermally controlled chamber to the pV/T Master volumetric analyzer allows for enhanced characterization of materials in the temperature range from just above zero ºC to over 100 ºC. This technical note presents a new instrumental and methodological approach for studying materials that can change their properties versus temperature and pressure, e.g. foams. |

A practical method for determination of mass loss of water and prediction of water content beyond the used temperature range is proposed. Using RH probe ensures selectivity towards water vapor instead of the total amount of gas/vapors loss like in gravimetric dynamic water vapor sorption analyzers. In addition to determining the mass of water loss, using either dry or humidified gas at various temperatures, the extracted volatiles can be delivered to other analytical devices.

|

|

Better implementation of the Bubble Point and Capillary Flow Porometer techniques are presented as optional capabilities that can be implemented in the pV/T Master volumetric analyzer. Improved theoretical approach and critical remarks that are often omitted in commercial marketing of such products are also presented.

|

To inquire about our products, please contact us at: [email protected]